Applications – Casting Area - BILLET, BEAM AND BEAM BLANK

Green Project has available all technologies used for marking the long cast products like the billets, blooms and beam blanks: stamping, tagging/labelling, paint, powder, metal spray.

Selection can be done according the Customer priorities which can be f.i. the durability of the marking, its readability from distance, the reliability of the system, the easy automatic recognition,

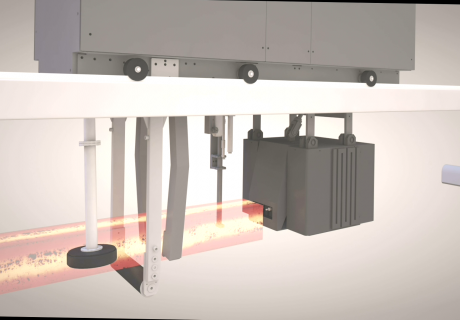

Green Project can offer marking machines with different configurations for installation in the run out area of the caster or aside the cooling bed or along the roller tables; they are therefore portals or railed basements with movable carriages, simple fixed units, robots equipped with various marking units. Typically they mark the cast product in stationary conditions, but there are also few models for marking during the conveyance.

The technologies offered by Green Project are:

Heavy Duty Stamping by PUMA HAMMER consisting of a chisel which deeply indents digits in the hot metal surface, even irregular, generally the cut section. It is the only system really permanent, resisting to impacts and all ambient conditions. It is also the fastest marking system on the market. It is independent from the scale, it’s very reliable and assures an excellent quality / cost rate. Digits can be read automatically by our fixed AURS units, also during conveyance. But it’s not very readable by eyes from distance.

Automatic Tagging or Labelling consisting of an automatic applicator which fixes a metal tag (resisting up to 1.200°C) or a special label (resisting up to 800°C) to the cut section. Tags and labels have a white printable coating; printing is typically letters, numbers, logos, 2D codes for automatic reading. Applicators can be robots or simpler electro-mechnical devices. Printed codes can be easily recognized by fixed or portable scanners. Durability of tags and labels is good but they are quite sensble to impacts during conveyance and manipulation.

Paint marking by TEMA system consisting of a paint marking unit which marks characters on the cut section (MONO) or the long faces (MULTI) of the cast products using special water base paints resisting up to 1.100 °C. Durability of the marking is good but. Symbols, even if sometimes affected by the irregular surfaces, are generally well readable from distance by eyes and also automatically by fixed AURS units. Typically robots are used to maipulate the marking unit.

Metal spray marking by SPRAY, consisting of a melting unit and a nozzle which sprays the melted metal drops, typically on the cut section of big blooms and beam blanks. Metal spray marking resists up to 1.200°C. Symbols are big, clear and well readable from distance and also automatically by fixed AURS units. They resist well to outdoor conditions, even if often the descaling of the surface before marking is required.

Powder spray marking by SPRAY, consisting of a nozzle which sprays a special metal powder (not melted), typically on the cut section of the cast products. Its features are similar to the metal spray marking. But the durability of the symbols is good but only in indoor conditions.

EN

EN

IT

IT