Applications - Rolling mills - BEAM AND BARS

For identifying beams of different shapes and sizes (H, U, angles, square, rounds…) and bars / rebars Green Project offers marking systems for both stationary and “on the fly” applications.

Beams, bars and rebars in static conditions are normally located on cooling beds or roller tables, single or in groups, and are marked on the section or on the side/top surfaces.

The marking technologies we propose are punching, paint / ink marking, laser marking, tagging / labelling.

When they are in groups (bundles of bars or coils of rebars), our solution is to indentify themby tags or labels, automatically applied by various technologies (hanged to the straps or spot / stud welded to the section).

In addition Green Project also developed the automatic ANTIMIX system for bundles of bars, including the 3D scanning of the bundle, the image acquisition, the spectrometric analysis of the bars to verify they are of the same kind, and the detection of the non conforming bars, which will be marked by paint or by other our marking technologies.

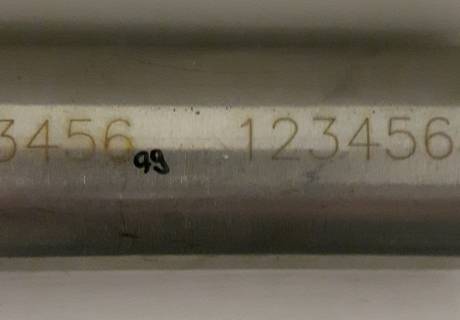

Beams in dynamic conditions are normally travelling along roller tables, at speed varying from few m/min to over 300 m/min. In this cases the marking is “one the fly”, i.e. during the conveyance.

The available technology is the TEMA paint / INK marking on the side / top surfaces.

The speed signal can be obtained by the Customer Automation or measured by an encoder device.

Special devices for blowing off oil, water, scale before marking are available.

Our automatic reading units (AURS), fixed or portable, are available to read a 2D code or directly the letters and numbers.

EN

EN

IT

IT